In construction, safety isn't just a goal; it's a non-negotiable priority. Amidst heavy machinery, skilled trades, and towering structures, the hierarchy of controls stand as a beacon of Workplace Health and Safety (WHS) management.

So, let's delve into what the hierarchy of controls (in WHS) entail.

Importantly, why it's a cornerstone in the construction industry, who shoulders its responsibility, and how it's implemented across various trades on a busy construction site. For more on hierarchy of controls (in WHS), read on.

Safety is an ongoing journey. Embrace the hierarchy of controls to create safer worksites.

Safety control measures

It's important to know what a safety control measure is, before learning about the hierarchy of controls. It will give you a practical understanding of hazard management, the need for a systematic approach, and the logic behind prioritising control methods based on their effectiveness.

For this reason, we'll outline safety control measures.

So, safety control measures encompass a range of strategies and actions implemented to manage and mitigate risks in various work settings. These measures act as barriers, reducing the likelihood and severity of harm to workers, visitors, and the environment. They're essentially the tactical moves that organisations take to keep everyone safe and sound.

How to implement safety control measures

Implementing safety control measures follows a systematic approach:

- Identification: Identify potential hazards through risk assessments and workplace inspections.

- Assessment: Evaluate the risks associated with each hazard, considering factors like likelihood and severity of harm.

- Selection: Choose appropriate control measures based on the identified risks. This could involve a combination of engineering, administrative, and PPE controls (explained below).

- Implementation: Put the chosen measures into action. This could mean installing safety guards, updating procedures, or providing workers with necessary protective gear.

- Monitoring and Review: Regular assessment of the effectiveness of each control measure. Make adjustments if circumstances change, or new risks emerge.

What is the Hierarchy of Controls in WHS?

The hierarchy of controls is a systematic approach used to manage risks in various work settings. It's all about tackling hazards in a structured way, starting with the most effective and reliable measures and progressing to less potent options if needed.

Most importantly, the goal is to keep everyone safe and healthy while ensuring optimal productivity.

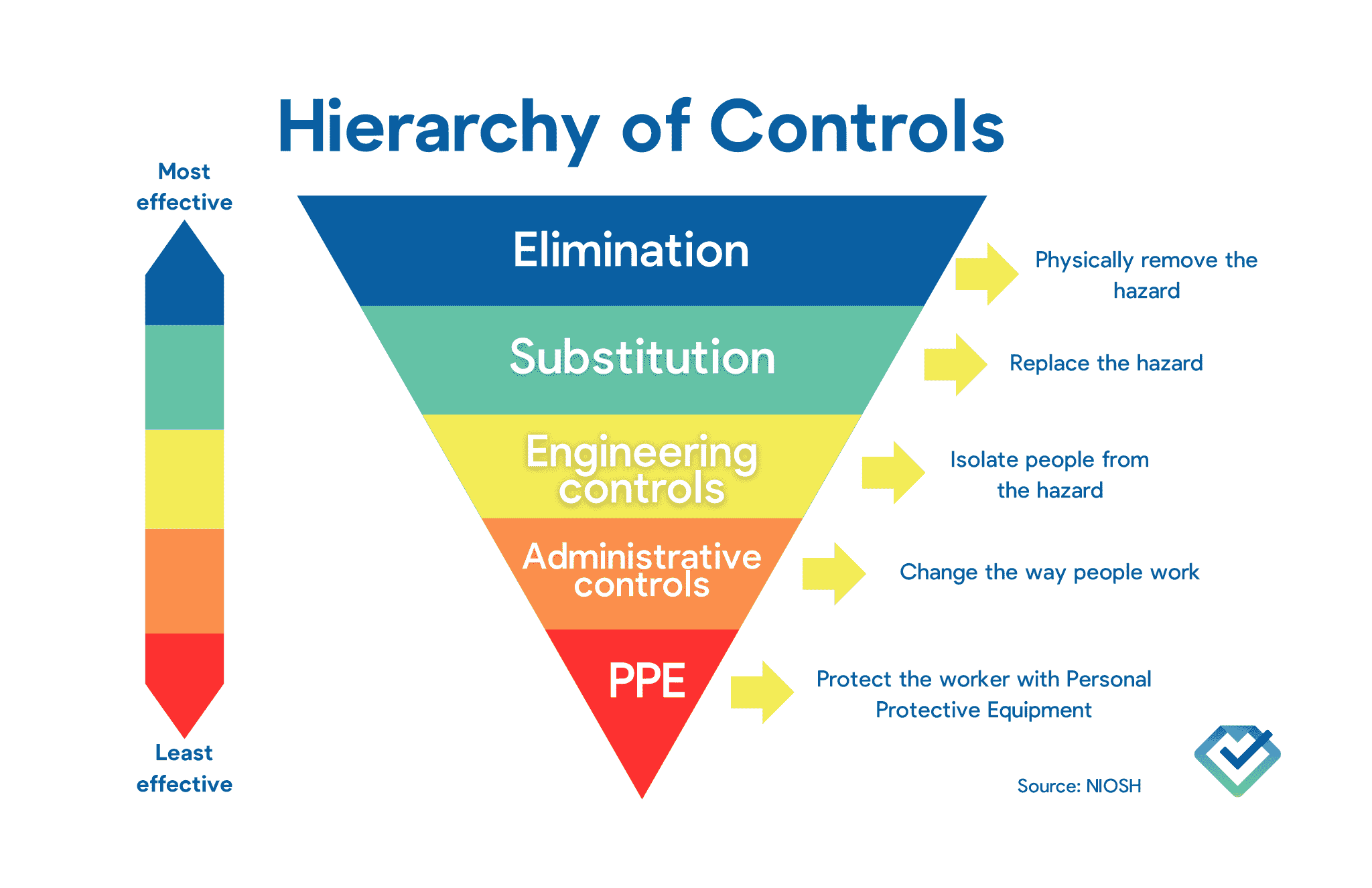

The Five Levels of Control:

The hierarchy has five levels. Each represents a different type of control measure:

- Elimination: At the top of the hierarchy is the gold standard – elimination. This involves completely removing the hazard from the workplace. Think of it as eliminating a potential threat at its source. For instance, if a toxic chemical is causing harm, eliminating its use altogether is the ideal solution.

- Substitution: If total elimination isn't possible, substitution comes into play. This means replacing a hazardous substance or process with something safer.

- Engineering Controls: These are physical modifications to the workplace or equipment to reduce exposure to hazards. It's about building a protective shield. Examples include installing ventilation systems to control airborne contaminants or placing barriers between workers and machinery.

- Administrative Controls: These measures focus on changing the way work is done to reduce risk. This might involve altering work procedures, setting up safety protocols, or creating warning systems. Administrative controls keep everyone on the same page.

- Personal Protective Equipment (PPE): The last line of defence, PPE includes gear like helmets, goggles, gloves, and masks that workers wear to protect themselves from hazards. PPE doesn't eliminate the hazard but acts as a barrier between it and the worker.

How to make the Hierarchy work

The hierarchy of controls isn't a one-size-fits-all approach. It's a tool that Principal Contractors and tradespeople tailor to their unique circumstances.

So, depending on the hazard, one or more levels of control might be needed. The goal is to start at the top and work your way down until an effective measure is found.

On construction sites, for example, in a Safe Work Method Statement, a Hierarchy of Controls system is used as a framework to control high-risk activities. The high-risk activity might be working at heights or working near traffic.

The person conducting high-risk work must ensure that controls are in place to manage risks to the health and safety of workers. Additionally, a copy of each SWMS is provided to the principal contractor before work commences.

To learn more about Safe Work Method Statements (SWMS), read “What is a SWMS?”

The Hierarchy of Controls in the Construction Industry

The construction industry, with its diversity of tasks and inherent risks, relies on the hierarchy of controls as a robust framework.

Moreover, it provides a strategic way to tackle hazards, ensuring that safety efforts are targeted and tailored.

By systematically applying controls, the industry mitigates risks, prevents accidents, and fosters a culture of safety.

The beauty of the hierarchy of controls lies in its adaptability to diverse trades. For example, each trade - be it carpentry, electrical, or excavation - requires tailored safety solutions.

For this reason, we've listed some examples:

- Elimination: For instance, in excavation, trench-less methods might eliminate the need for traditional trenching, thus eradicating the associated risks.

- Substitution: Substituting hazardous materials with safer alternatives is prevalent. An electrician may opt for less toxic insulation materials.

- Engineering Controls: Carpenters could employ scaffolding or guardrails as physical barriers to prevent falls from heights.

- Administrative Controls: Clear signage and controlled access zones for workers can minimise risks in high-traffic areas.

- Personal Protective Equipment (PPE): In various trades, from welding to concrete pouring, PPE such as helmets, gloves, and eye protection form the last line of defence.

Who is responsible for managing the hierarchy of controls at a construction site?

The mantle of responsibility for managing the hierarchy of controls rests on the shoulders of multiple stakeholders. From project managers to supervisors and workers, each plays a vital role. However, the ultimate responsibility often falls on the shoulders of the Principal Contractor, who orchestrates and oversees the holistic safety strategy on site.

Where is the Hierarchy of Controls Stored on Site?

The hierarchy of controls is typically documented within the site's safety management plan. It's an accessible guide for workers, contractors, and stakeholders, and serves as a navigational tool in the complex safety landscape.

Why Safety Control Measures Matter

Implementing effective control measures not only safeguards workers, but also benefits organisations.

They lead to a reduction in accidents and injuries, lower absenteeism, increased employee morale, and enhanced productivity. Moreover, compliance with safety regulations ensures legal and ethical obligations are met.

In conclusion, the hierarchy of controls isn't just a strategy; it's a commitment to the well-being of every individual on a construction site. By systematically prioritising safety measures, the construction industry fortifies its foundations, and builds a future that's both sturdy and secure.

Remember, safety is an ongoing journey, and embracing the hierarchy of controls for WHS is an active step toward safe worksites.

Safety Management Plans (WHS)

Specifically designed for each trade starting up a business, these Work Health Safety Management Plans or WHS Management Plans, provide support with the management of Work Health & Safety in the workplace. Also referred to as Occupational Health & Safety (OH&S) the material provided in this section will assist with WHS/OHS management and training requirements for the workplace.